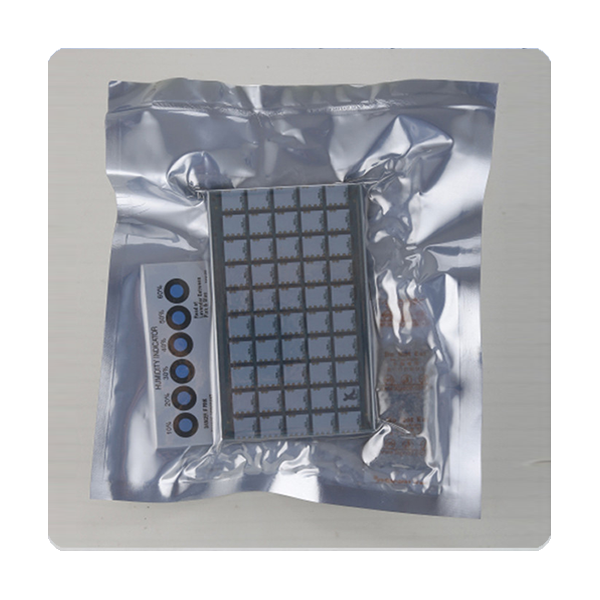

VCI Foil

Product Description VCI FOIL FILM

VCI Foil film is manufactured using a technical process and structure. The film is manufactured on a 3 layer, multilayer co-extrusion plant combined with a foil barrier layer and a polyester layer. The combined structure offers a very low oxygen and water vapor permeability combined with VCI properties.The film comprises of total 5 layers. During the packaging process vacuming out is not required, because the inner and middle function as VCI transmitting layers.

VCI Foil Specifications

| Product Information | |

| Appearance | |

| Protected Metal Types | |

| Protection Duration | |

| Storage |

Outermost layer serves as a barrier layer to control the uni-directional transfer of VCI chemicals as well as provide improved barrier properties to the film. The aluminium outer barrier layer laminated to the 3 Layer VCI Film provides higher strength barrier to the water vapor and oxygen molecules.

The VCI molecules work by evaporation and condensation on the cooler metal parts and prevent corrosion wherever they settle. In effect a corrosion inhibiting layer comprising of macro-molecules is deposited on the part.

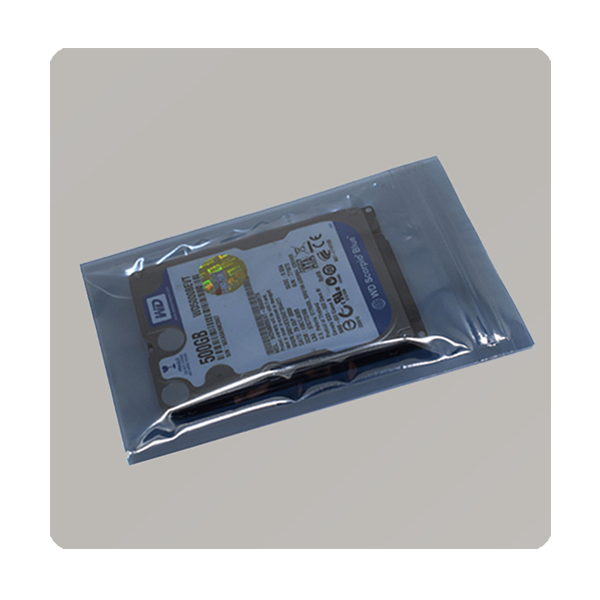

This works by preventing the forward reaction of corrosion by inhibiting electron flow, altering pH as well as by forming a physical barrier to oxygen and water vapor.These bags can be heat sealed using ordinary heat sealing machine or can also be provided with a self-sealable adhesive tape which can be removed to form a sealed packaging system .

This works by preventing the forward reaction of corrosion by inhibiting electron flow, altering pH as well as by forming a physical barrier to oxygen and water vapor.These bags can be heat sealed using ordinary heat sealing machine or can also be provided with a self-sealable adhesive tape which can be removed to form a sealed packaging system .

Due to the advanced VCI Action there is no need to vacuum the packaging as the moisture and air are treated with VCI. VCI Foil film use in development of packaging and packing for lots of products in different industries.

Product consulting

You can gain access to more information via our product database or by consulting our specialists and techniccians who will gladly get in contact with you